Custom Structural Aluminum Assembly Table

for Four Sons Woodworks

At Quality VAKuum Products , we are known for our vacuum presses and veneering systems. But did you know we also build custom modular workstations? A recent project with Four Sons Woodworks is a perfect example of how we help customers solve shop layout challenges with smart, modular design.

🔧 Project Specs

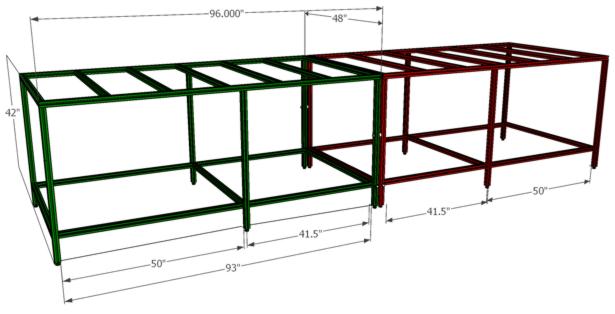

The customer needed a large, flat, stable surface for assembly tasks. Their request: a table measuring 4 feet wide by 16 feet long, with 40" tall legs and a

finished height of 42 inches using standard leveling feet.

Rather than build and ship one oversized frame, we suggested a smarter solution: construct two modular 4' x 8' tables that bolt together. This design allowed

us to ship the entire setup as a knock down kit. Making it more cost-effective and far easier to transport.

To make assembly simple, all components were clearly labeled and included detailed instructions. We even provide step-by-step assembly videos to guide

customers through the build process with confidence.

🏗 Built with T-Slot Structural Aluminum

This workstation was built using 1.5" x 1.5" t-slot aluminum, our go-to material for custom shop tables. T-slot aluminum offers:

- Strength and rigidity

- Modular expandability

- Easy adjustments

- Lightweight but heavy-duty performance

🛠 ️ Assembly Overview

Assembly was straightforward, thanks to pre-labeled parts and detailed instructions:

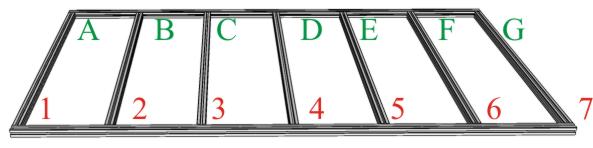

1. Top Frame Construction - Letter side and number side stiles were laid out, with 7 cross rails slid into place using labeled guide marks.

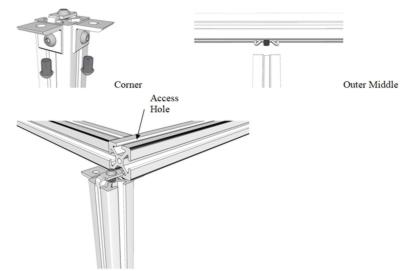

2. Leg Installation - Legs were attached using a floating C-clip system that locks to access holes, no guesswork required.

3. Lower Stile Assembly - Lower stiles were installed 6 inches off the floor for added strength and shelving potential.

4. Anti-Splay Bracing - AKA lower rails. Cross bracing ensures long-term rigidity and squareness.

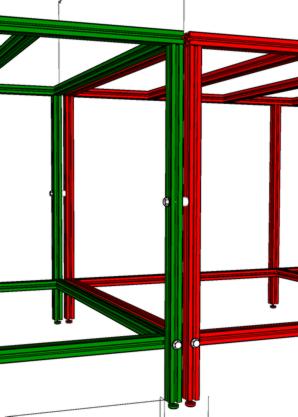

5. Final Bolt-Up and Table Connection - The two tables were joined with pre-drilled holes using bolts, spacers, washers, and

nuts - all included.

🧰 In the Customer's Shop

Here's the final table fully assembled and in use at Four Sons Woodworks. Topped with plywood and fully loaded with tools and supplies. The result? A rock-solid workbench with excellent storage and workflow optimization.

✅ Why We Recommended a Multi-Table Design

- Lower shipping cost

- Simplified installation

- Modular flexibility for future expansion

- Stronger shipping protection with smaller packages

Need a Custom Table for Your Shop?

📞 Call us at 800-547-5484

📧 Email: qvp@qualityvak.com

🌐 Visit: www.qualityvak.com