Q.V.P. Blog

Vacuum veneering and laminating techniques a comprehensive guide

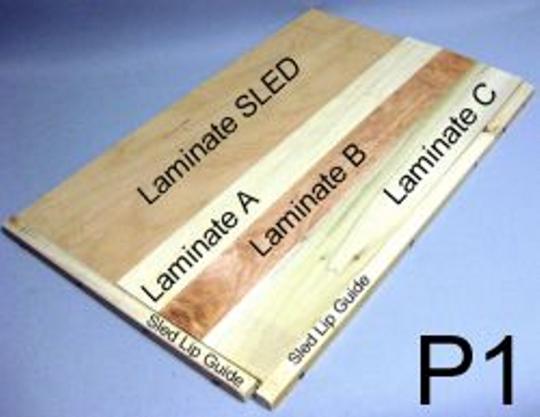

This guide will walk you through the process of veneering a raised panel door using a vacuum press. Key elements for success include the panel shape and veneer flexibility.

If you often work with large panels or heavy items, a vacuum frame presscan be incredibly useful. Unlike traditional vacuum bags, where you

have to load and unload pieces manually, a frame press lets you prepare your panels on a table, close the lid, and apply the vacuum with ease.

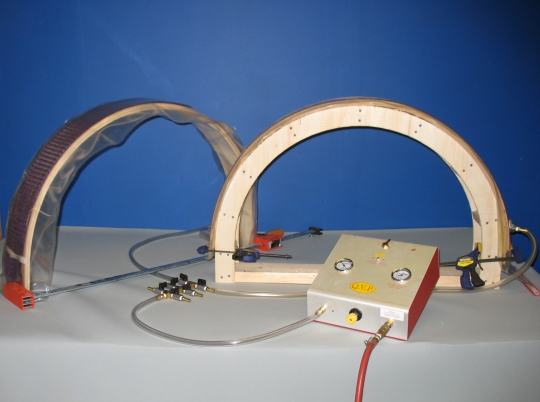

Vacuum laminating with the form outside of the bag is a great way to save time and money when forming materials into shapes, whether you're working with simple

curves or complex structures like spiral staircases. Here's why this method is beneficial and how you can use it to make a curved arch or jamb.

In addition to our expertise in vacuum technology, we offer a comprehensive range of structural aluminum products and services, designed to meet diverse industry needs.

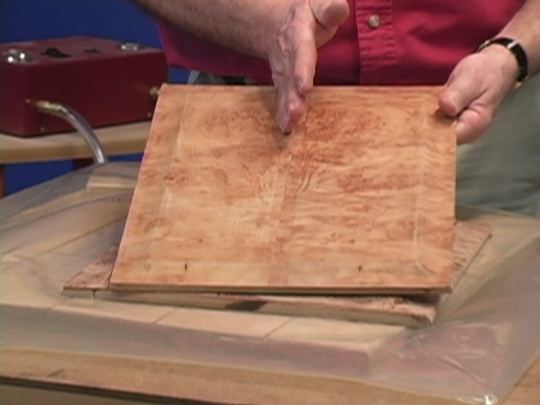

When working with raw wood veneers, it's essential to ensure the veneer is flat and flexible before use. If a veneer is too dry or wavy, it can crack during the pressing process, especially when applied to curved surfaces like raised panel doors. For a smooth application, the veneer must easily conform to the surface it’s being applied to.

Using a vacuum press to form leather offers precision, efficiency, and the ability to create intricate shapes that are difficult to achieve by traditional hand-forming methods. While this process is often associated with woodworking or composites, it has gained popularity in leatherworking

for crafting high-end goods such as wallets, belts, armor, shoes, and molded cases.

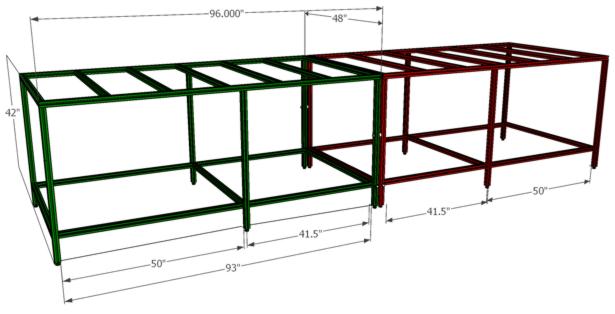

At Quality VAKuum Products (Q.V.P.), we have extensive experience designing and manufacturing table stands for vacuum frame presses. Our expertise lies in utilizing heavy-duty T-slot structural aluminum, which we’ve developed in-house.

Creating a reliable form for vacuum pressing requires precision, strength, and attention to detail. Below is a step-by-step guide to ensure your form can withstand up to 1,800 lbs./sq.ft. of

pressure, ensuring your projects are executed safely and accurately.

Vacuum clamping is a game-changer in the woodworking shop. Many users say things like, "It's like having a third hand!" or "I don't know how I’d manage without it." If you

have a vacuum pump, chances are you can start using vacuum clamping right away to make your work easier, safer, and more precise.

Edge gluing is a reliable method for joining thin wooden slats for applications like decorative flooring, panel making, or inlays. When done correctly, the

results are high-quality, smooth, and durable.

A vacuum veneer bag is a valuable tool for achieving high-quality, even pressure across veneers, but over time, it can develop leaks. Identifying and fixing

these leaks will help maintain an efficient and reliable vacuum system.

Air-powered vacuum pumps, also known as Venturi pumps, are an excellent choice in woodworking and other demanding environments. One of their biggest

advantages is their impressive reliability—they have no moving parts like traditional electric pumps, which makes them especially suitable for dusty woodworking shops where dust and debris can easily

damage electric pump components.

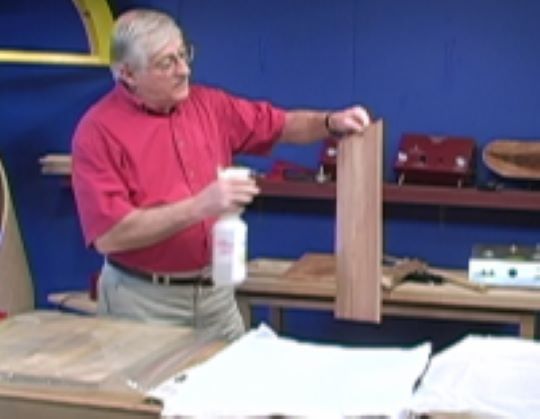

Glue application is a critical step in woodworking, laminating, and other construction processes. Using an effective tool for this step can mean the difference between a strong, clean

bond and a mess of overapplied glue, wasted product, and uneven results. For those looking to streamline and improve their adhesive application process, handheld glue spreaders are an invaluable asset.

The holiday season is the perfect time to create unique, personalized decorations, and what better way to do so than by combining modern technology with traditional craftsmanship? In this

tutorial, we’ll walk you through the process of using a laser engraver to cut intricate veneer designs, then bonding them to a board with the help of a vacuum press.

At Quality VAKuum Products , we’re known for our vacuum presses and veneering systems — but did

you know we also build custom modular workstations? A recent project with Four Sons Woodworks is a perfect example of how we help customers solve shop layout

challenges with smart, modular design.

Curved woodwork has always captured the imagination of furniture makers, architects, and hobbyists alike. From sweeping chair backs to elegant table aprons, bent

laminations make it possible to achieve flowing designs that solid wood simply cannot provide. Traditionally, these curves require rigid molds, dozens of

clamps, or even steam-bending setups.

Are you looking for the functionality of a flip-top frame press but can’t quite justify the cost or the permanent space it requires in your

shop? There’s a simple solution that gives you the same flexibility at a fraction of the price - a traditional stock-size vacuum bag that

opens on three sides instead of just one.

Cold weather impacts every part of the veneering and laminating process, from how glue cures to how flexible your

vacuum bag feels. Luckily, with a few simple adjustments, you can

keep your workflow steady and your results strong all winter long. By managing temperature, adding gentle heat, and keeping

your materials conditioned, you’ll prevent the common cold weather issues that slow production and compromise quality.