A Lower Cost Alternative to Flip-Top Frame Presses:

Multi-Side Opening Vacuum Bags

Are you looking for the functionality of a flip-top frame press but can't quite justify the cost or the permanent space it requires in your

shop? There's a simple solution that gives you the same flexibility at a fraction of the price - a traditional stock-size vacuum bag that

opens on three sides instead of just one.

With this setup, you'll be able to flip the bag wide open, easily load your workpiece and form, then close it securely with our C-channel closure

system. Let's walk through how it works.

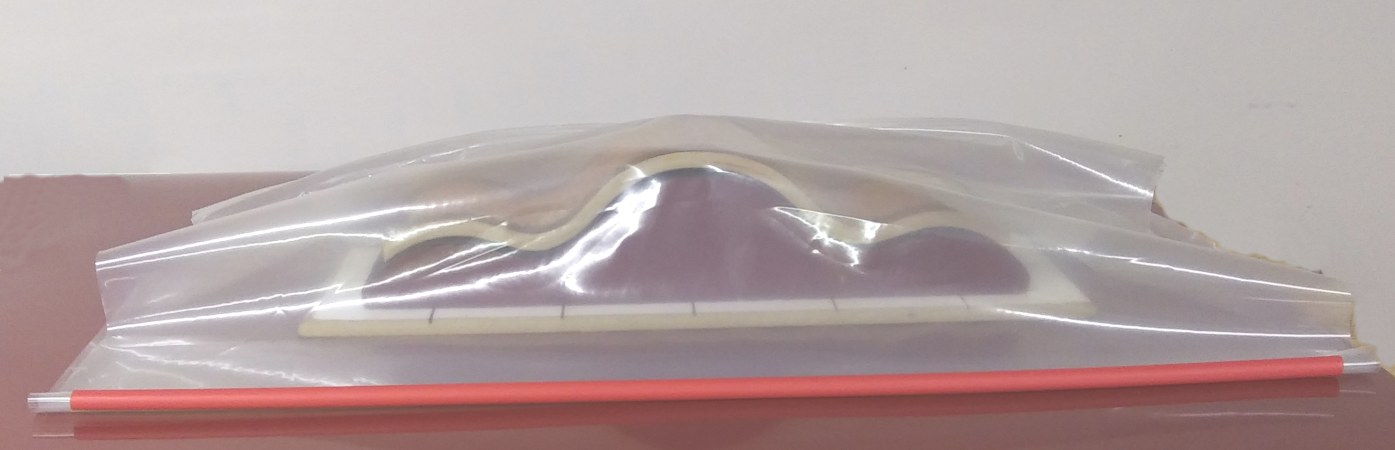

Step 1 - Preparing the Form

Here we've set up a curved form and veneer layup. Instead of struggling to slide this into a single-opening bag, the bag lies completely flat and open on three sides, making it easy to place the assembly right on the grid board.

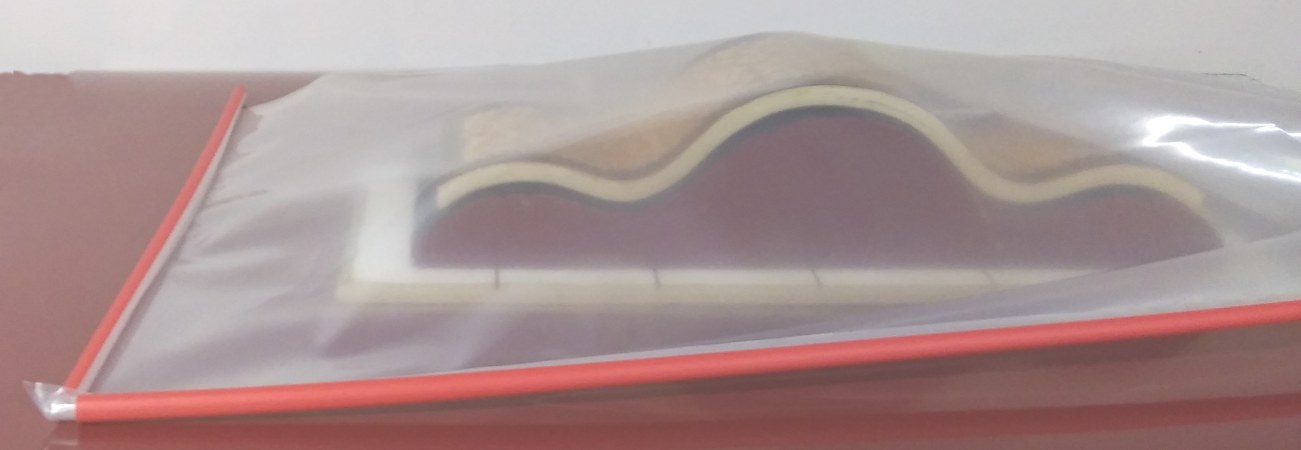

Step 2 - Flipping the Bag Over

Once the layup is positioned, simply flip the bag over the workpiece. Because three sides are open, you get full access without forcing material in from a single narrow opening.

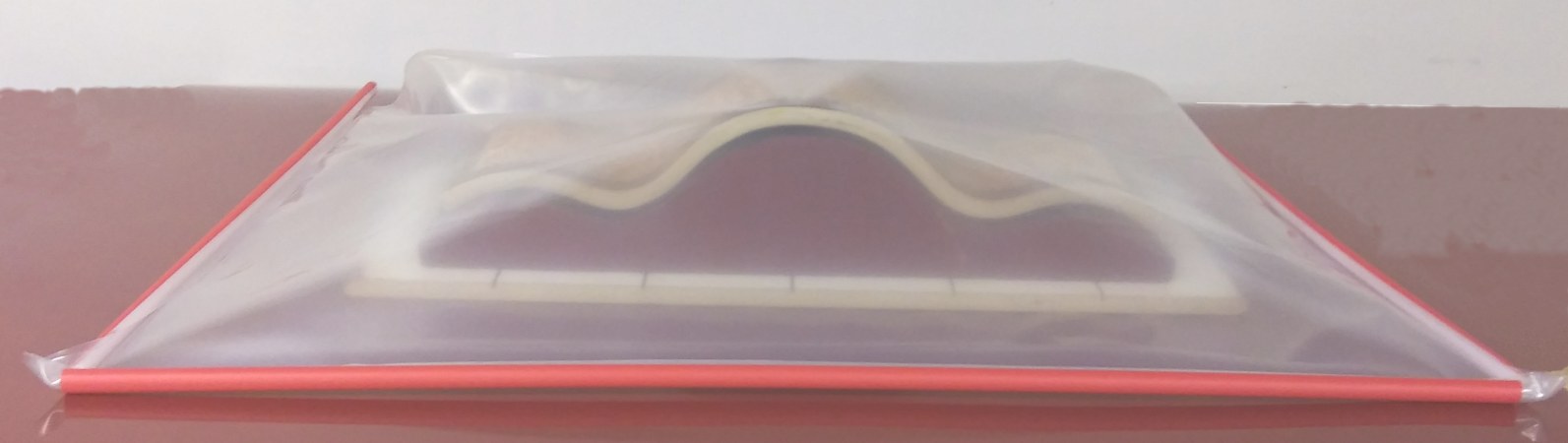

Step 3 - Sealing the Bag

After flipping, use the red C-channel closure system to seal each open side. It takes a little longer to close than a hinged frame press, but the result is airtight and reliable.

Step 4 - Applying Vacuum Pressure

With the bag sealed, connect it to your pump and pull vacuum. The film conforms perfectly around even complex shapes, applying even pressure across every curve.

Step 5 - Easy Storage When You're Done

Here's the real advantage: once your pressing is complete, simply remove the grid board, roll up the bag, and place it back in its box. No bulky frame press

taking up valuable floor space - just performance on demand, with the convenience of storage.

Limited Time Offer

Valid through October 31, 2025All our vacuum bags will be offered as 3 sided bags with c channel closures at no extra cost. Just mention that you want the bag to be open 3 sides instead of one.