Electric Instructions -

ES5 Super-Pro AUTOMATIC SET-UP DIAGRAM AUTOMATIC VAKUUM BAG OR FRAME PRESS VENEERING with bag manifold

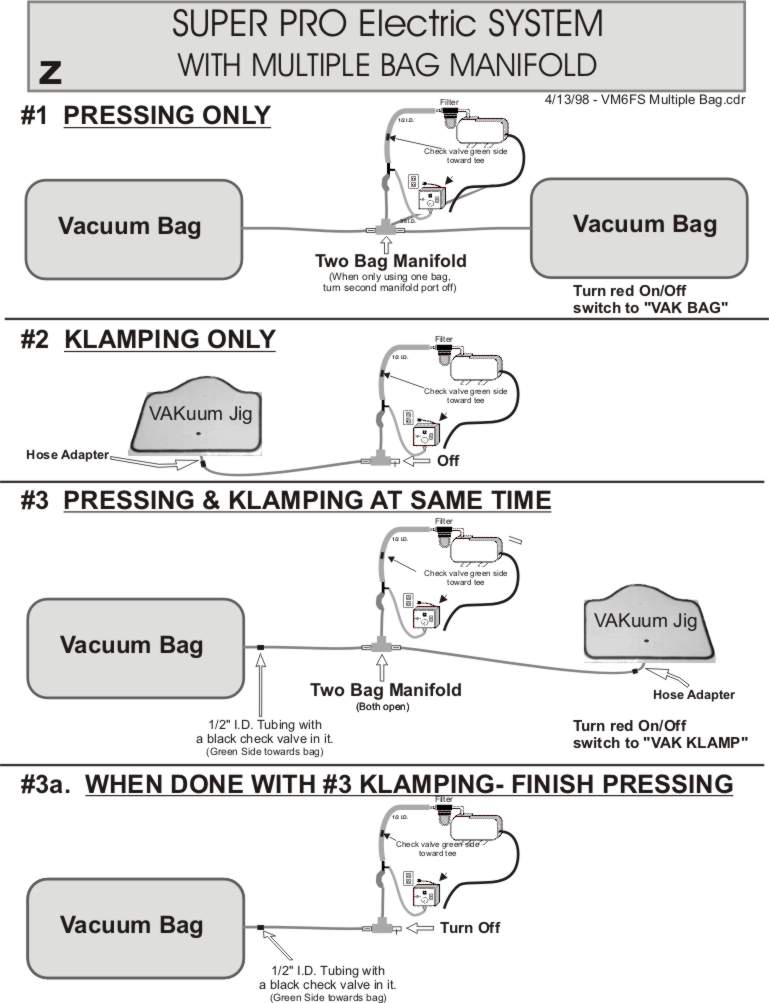

Your SUPER PRO Electric Pump (5 CFM) can operate multiple vacuum bags or frame presses at the same time using the

Two-Bag Manifold. This versatile setup also lets you veneer/laminate in a VAKuum Bag while simultaneously using the

system for VAKuum Klamping (hold-down work).

Below are instructions for all four operating modes shown in the diagram.

#1 – PRESSING ONLY (Using One or More Vacuum Bags)

When using the system strictly for veneering or laminating:

- Connect vacuum bag(s) to the Two-Bag Manifold.

- If only one bag is being used, close the unused manifold port.

- Ensure the black check valve is installed with the green side toward the bag.

- Turn the red On/Off switch to “VAK BAG.”

- Allow the pump to evacuate the bag(s) until full vacuum is achieved.

This mode is used for standard veneer pressing or lamination in one or two bags simultaneously.

#2 – KLAMPING ONLY (Using a VAKuum Jig)

When using the pump as a vacuum hold-down/clamping tool:

- Attach the VAKuum Jig to the pump using your hose and adapter.

- Turn the red On/Off switch to “VAK KLAMP.”

- The VAKuum Jig will hold your workpiece secure for routing, sanding, shaping, etc.

- The manifold ports are not used in this mode—leave them off.

Use this mode any time you need hands-free clamping or panel hold-down capability.

#3 – PRESSING & KLAMPING AT THE SAME TIME

The system is designed to press veneers and use clamping tools simultaneously.

- Connect vacuum bag(s) to the Two-Bag Manifold. Both manifold ports remain open when using two bags.

- Connect the VAKuum Jig using the hose adapter.

- Insert ½" I.D. tubing with a black check valve installed before the bag. Green side toward the bag.

- Turn the red switch to “VAK KLAMP” so both the bag(s) and the jig receive vacuum.

- The pump will maintain vacuum in all connected tools simultaneously.

This is the ideal setup for customers who need to laminate large parts while clamping smaller components at the same time without stopping production.

#3a – WHEN DONE KLAMPING – FINISH PRESSING ONLY

After completing the hold-down portion and removing the piece from the VAKuum Jig:

- Disconnect the VAKuum Jig.

- Turn off the VAK KLAMP line.

- Leave the bag connected through the check-valve tubing.

- The pump continues pressing the bag(s) normally to finish the veneer or lamination cycle.

This automatically isolates the bag and maintains pressure without losing vacuum.

General Notes & Best Practices

- Always confirm the check valve orientation—green side faces the bag, black side faces the pump.

- When running multiple bags, ensure unused manifold ports are shut off.

- Keep the filter clean for best performance.

- Never place the pump where it can draw dust or glue particles directly.

- The system is designed to maintain vacuum automatically—no manual balancing is needed.