NU-Matic Instructions

How to assemble your NU-Matic Controller

1. Required Air Pressure

- The NU-Matic must operate between 85–100 psi.

- Do NOT exceed 100 psi. Higher pressure can damage internal components.

2. Clean, Filtered Air Is Essential

- Always supply the unit with clean, filtered air.

- If you use quick disconnect fittings, make sure the female connector is clean before attaching it.

- Picking up an air hose connector from the floor may introduce sawdust, chips, or debris into the system.

- Any contamination blown into the NU-Matic can cause performance issues or damage.

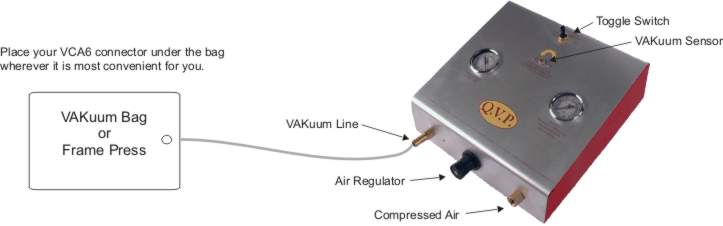

3. Understanding the Toggle Switch

- The NU-Matic has a three-position toggle switch located on the top center of the unit.

-

This switch allows you to run the pump:

A. Continuously, or

B. In regulated mode when used with a VAKuum Bag or Frame Press.

4. Setup Instructions

Step 1 – Connect the Air Supply Attach your air line to the right-side fitting (1/4" NPT).

Step 2 – Connect the Vacuum Line

- Attach the vacuum hose to the barbed fitting on the left side of the unit.

- Block the open end of the vacuum hose with your thumb.

- Flip the toggle switch to "VAK Bag" mode.

- The unit should pull vacuum up to 25" Hg and then automatically shut off.

5. Adjustments & Controls

Air Regulator (Black Knob on Front Center)

- Adjust this knob only when the unit is running.

- The air pressure gauge must read 85–100 psi while operating.

- If pressure is below 85 psi, the unit may fail to reach full vacuum and may not shut off automatically.

VAKuum Sensor Adjustment

- Brass screw located just below the toggle switch.

- Turning the sensor counter-clockwise makes the pump shut off at a lower vacuum level.

- Do not adjust this sensor unless:

A - You intentionally want lower vacuum pressure (for weaker forms), or

B - Your air supply cannot reach full vacuum.