A User-Friendly Guide to Edge Gluing Thin Slats for Panels and Decorative Flooring

Edge gluing is a reliable method for joining thin wooden slats for applications like decorative flooring, panel making, or inlays. When done correctly, the

results are high-quality, smooth, and durable. A vacuum press is a great tool to ensure strong bonds, but success hinges on two key factors: straight

edges and uniform thickness of your slats. Even if the slats have minor warping, the 1800 lbs/sq.ft. pressure applied by the press can flatten them effectively.

This guide walks you through two methods for edge gluing and explains how to use a sled to apply even pressure. Let’s break it down step by step.

What You Need to Get Started

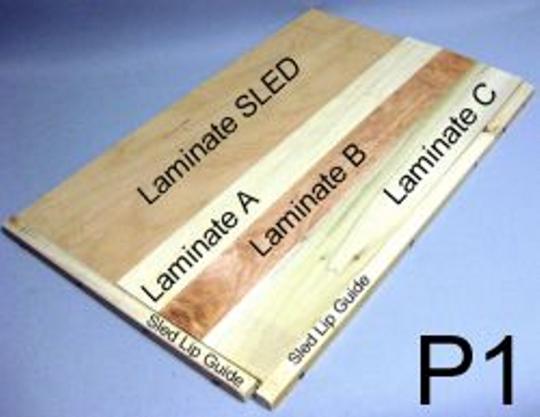

Sled: A sled holds the slats securely in place during pressing. (P1)

Base Material: Plywood or MDF.

Right-Angle Fixture: Attach a 90-degree corner piece along one side and one end to align your slats. Sled lip guide as seen in P1.

Height Adjustment: The height of the right-angle corner should be about 1/8" shorter than the thickness of your final piece.

Coating: To prevent glue from sticking the workpiece to the sled, coat the sled with a non-stick finish (such as a release agent or wax).

Rounded Edges: All sled edges should be rounded to avoid puncturing the vacuum bag or

frame press top.

Method 1: Traditional Sled Pressing

This technique works well for uniform slats of the same thickness and width, making it ideal for decorative flooring and inlays. Here’s how it works:

Setting the Slats:

- Apply glue along the edges of the slats.

- Align them in the sled, pressing them against the right-angle fixture.

- Place a thin strip of plastic between each lay-up to prevent glue squeeze-out from sticking multiple layers together.

Using a Vacuum Press:

Slide the sled into a vacuum bag or place it in a vacuum frame press. (P2)

The vacuum up to 1,800 pounds of pressure per square foot across the slats. For example:

A 3/8" edge provides 4.5 sq. in. of surface area per linear foot.

This increases the contact area and can double the pressure to 800 pounds along the 8' length.

Increasing Pressure:

For additional side pressure, add a ¾" x ¾" x 8' strip along the open edge of the sled. (P3)

This increases the contact area and can double the pressure up to 800 pounds along the 8' length

Pro Tip:

If your slats are cut with high precision, this extra step may not be necessary. Simply apply hand pressure to align the edges while the vacuum pulls tight.

Method 2: Wedge Pressing for Irregular Slats

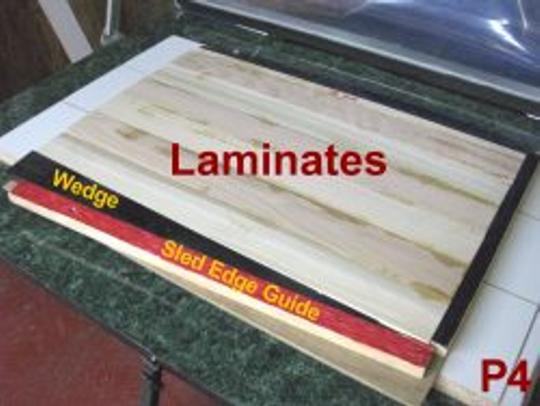

This method is ideal for slats with varying widths or thicknesses, such as bamboo panels. Here’s how to use wedges to apply edge pressure:

Preparing the Sled:

- Make the sled about 3 inches wider than your panel to accommodate the wedge mechanism.

- Attach an angled stop along the extra 3" section to hold the wedge securely.

Setting the Slats:

- Lay the slats inside the sled, aligning them against the right-angle fixture.

- Keep adding slats until the total width exceeds your desired panel width by a small overhang (e.g., for a 4' panel, aim for 4' + a slight overhang).

Inserting the Wedge:

- Insert a wedge along the angled stop to force the slats together. (P4)

- As you apply pressure with the wedge, the slats may buckle slightly, which is okay. The vacuum press will flatten them during the pressing process.

Using a Vacuum Press:

- When placed in the vacuum bag, the 1800 lbs/sq.ft. pressure presses the slats flat, ensuring a tight bond.

- This method works even with slats of varying thickness because the vacuum applies even pressure across the entire surface.(P5)

Scaling Production with Multiple Sleds

If you want to increase productivity, consider using a frame press that holds multiple sleds stacked vertically. Here’s how:

Stacking Sleds:

- In a 24" high frame press, you can place several sleds one on top of the other.

- The bottom of each sled serves as a caul, pressing down on the slats below it.

Using a Compression Mat:

- If your slats vary in thickness, place a compression mat between layers.

- The mat adjusts to the slats' thickness differences, ensuring consistent pressure and a smooth, flat panel surface.

Key Tips for Success

Check for Straight Edges: Even a slight misalignment can result in uneven joints.

Control Glue Application: Apply glue evenly to avoid gaps or weak spots, and use plastic strips to prevent unwanted bonding.

Use a vacuum press Use a Q.V.P. air-powered or electric

vacuum press to maintain effecient vacuum for your panels.

By following these methods, you can achieve smooth, high-quality glued panels and decorative flooring with minimal hassle. Whether you’re working with precise slats

or irregular materials like bamboo, the sled and vacuum press setup ensures durable, flat surfaces every time.

Video Link - Learn how to edge glue thin slats for flawless panels and decorative flooring with these easy vacuum press techniques!