Hand Held Glue Spreader

Understanding the Efficiency and Precision of 5.5" and 7" Handheld Glue Spreaders

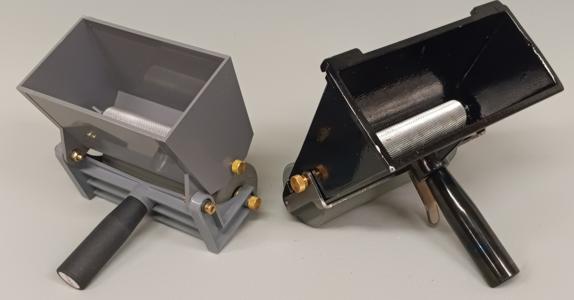

Glue application is a critical step in woodworking, laminating, and other construction processes. Using an effective tool for this step can mean the difference between a strong, clean bond and a mess of overapplied glue, wasted product, and uneven results. For those looking to streamline and improve their adhesive application process, handheld glue spreaders are an invaluable asset. Here, we’ll focus on two popular models: the 5.5" (GS5) and 7" (GS7) handheld glue spreaders, each designed to boost efficiency and reduce waste.

Overview of the Glue Spreaders

The GS5 and GS7 handheld glue spreaders are engineered for precision and ease of use. These spreaders come equipped with hoppers, small storage compartments

that hold glue allowing users to load glue into the spreader for an even, controlled application.

Each model has unique features tailored to different project sizes:

5.5" Handheld Glue Spreader (GS5): Equipped with a 1-quart hopper, this spreader is ideal for smaller, more detailed work. The GS5 width offers excellent control over narrower surfaces

and helps users avoid unnecessary glue spills.

7" Handheld Glue Spreader: (GS7) The 7” model comes with a larger, 2-quart hopper, suitable for larger projects. With its increased width and capacity, the GS7 spreader

is designed to handle tasks like applying glue to a standard 4’ x 8’ sheet in a single session.

Let’s explore the individual advantages these models offer and how they can help improve both quality and productivity.

Key Features and Advantages of the 5.5” and 7” Glue Spreaders

1. Enhanced Glue Capacity

The 1-quart hopper in the GS5 spreader and the 2-quart hopper in the GS7 spreader offer a significant advantage over traditional hand-spreading techniques. By holding enough glue to cover large

surface areas without needing frequent refills, these hoppers make large applications more efficient and reduce interruptions in workflow.

5.5" Spreader (GS5): Ideal for projects that don’t require a massive amount of glue or for working on smaller surfaces.

7" Spreader: (GS7) With a 2-quart hopper, this model can cover a 4’ x 8’ sheet, making it suitable for larger applications where glue needs to be applied evenly over a broad area.

2. Uniform Glue Distribution

Achieving even glue coverage is crucial for a strong bond, but manually spreading glue often leads to over- or under-application, compromising the quality of the final product. The precision mechanisms

in these spreaders distribute glue evenly, ensuring that the surface is covered without excess or gaps, leading to a consistent adhesive layer.

3. Dual Functionality: Spreading Without Releasing

Both the GS5 and GS7 spreaders have a unique feature that allows users to spread glue across a surface without continuously releasing additional adhesive. This feature is especially useful for fine-tuning

the glue layer without oversaturating the workpiece.

Imagine the flexibility: you can initiate glue application, stop the release, and continue smoothing out the layer as needed, all with the same tool. This functionality reduces wastage and gives users more

control over the glue application process.

4. Time and Cost Efficiency

When it comes to production environments, time is money. Every minute saved on manual glue application translates to higher productivity and, ultimately, increased profitability. Here’s how these spreaders

contribute to cost efficiency:

Faster Production: With larger hoppers and uniform distribution, these spreaders eliminate the time-consuming process of frequent glue reloads and manual spreading.

Reduced Material Waste: The precision glue release mechanism ensures that only the needed amount of glue is applied. This reduces glue wastage, which can add up over

time in high-production settings.

Less Cleanup: Overapplication not only wastes glue but also creates a mess that requires cleanup. The controlled application reduces excess glue spillage and minimizes

the need for extra labor and time for cleaning, leading to cleaner work environments.

Practical Applications of GS5 and GS7 Handheld Glue Spreaders

These glue spreaders can be utilized across a variety of industries, including woodworking, furniture making, cabinetry, and even some light construction. Below are a few ways these tools bring value to

different types of projects:

1. Woodworking and Cabinetry

Precision and durability are essential in woodworking. Using a handheld glue spreader ensures a clean, even layer that forms a strong bond between wood pieces, essential for high-quality joinery. With a

reliable spreader, users avoid bubbles, gaps, and uneven drying, which are often issues with hand application.

2. Furniture Manufacturing

In furniture production, especially when dealing with veneers or laminates, it’s crucial to have a reliable adhesive layer. The GS7 glue spreader with its 2-quart hopper is perfect for this application

as it holds enough glue to cover larger surfaces without frequent reloads. The even application helps prevent weak bonding areas, a common issue that can lead to early deterioration in furniture pieces.

3. Laminate and Veneer Applications

Laminating large sheets of veneer or laminate requires careful glue distribution to avoid bubbling or uneven surfaces. With the GS7 glue spreader, users can quickly cover a 4’ x 8’ sheet, making it an

invaluable tool for laminate professionals.

4. Assembly Lines and Production Facilities

In high-production environments, tools that streamline repetitive tasks are essential. The handheld glue spreaders, with their large capacity and controlled application, allow workers to efficiently handle

large volumes of adhesive work. With less downtime for refilling or cleaning up spills, production lines can move faster and deliver consistent results.

Benefits to Your Bottom Line

For businesses, time saved is money earned. By using these GS5 and GS7 handheld glue spreaders, companies can see substantial savings in both labor and

material costs. Here’s a breakdown of the financial advantages:

1. Reduced Material Waste: The precision application mechanism reduces the likelihood of overapplying glue, helping cut down on wasted adhesive.

2. Increased Productivity: By minimizing the time spent on refilling, applying, and cleaning up glue, workers can focus on additional tasks, increasing output.

3. Less Rework: With even glue application, products have a stronger bond, meaning fewer repairs or redos are necessary. This reduces waste and enhances customer satisfaction.

Lower Overhead Costs: With a cleaner, more efficient workflow, there’s less downtime for cleanup, leading to reduced operational costs.

Conclusion:

The GS5 and GS7 handheld glue spreaders are indispensable tools for anyone working with adhesives, from hobbyist woodworkers to large-scale production

facilities. With benefits such as controlled glue release, reduced waste, increased efficiency, and easy maintenance, these spreaders are a sound investment that pays off quickly in both saved time and

materials. Whether you're looking to boost production speed, reduce glue consumption, or achieve more precise results, these handheld glue spreaders offer an ideal solution for a wide range of adhesive applications.

By incorporating these tools into your workflow, you’re not only making your processes more efficient—you’re also investing in the quality and durability of your final products.

Click here to watch a short video on the GS5 and GS7 hand held glue spreaders