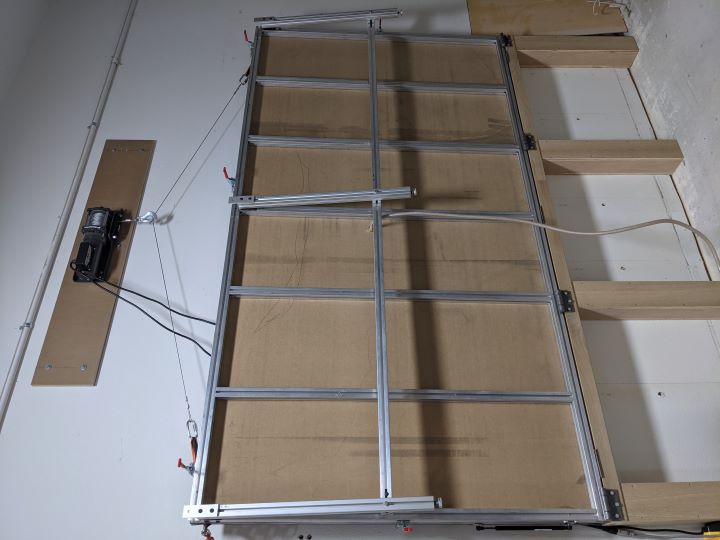

Wall hung vacuum frame press with truck winch

If you often work with large panels or heavy items, a vacuum frame press can be incredibly useful. Unlike traditional

vacuum bags ,where you have to load and unload pieces manually, a frame press lets you prepare your panels on a table,

close the lid, and apply the vacuum with ease.

Frame presses tend to be on the larger side and can make a big foot print in your shop. To solve this, our wall-mounted frame press is a great option.

It gives you the benefits of a frame press but can be flipped up against the wall when not in use, saving space. You can even load a flat panel, start the pressing

process, and then flip the press against the wall while the glue dries. This makes it a must-have for shops with limited room.

This is what the wall mounted frame looks like before adding the table top. It is suggested to assemble the table stand part first and attach it to the wall to adjust for level.

The wall-mounted vacuum frame press is shipped as a kit for easier and more affordable shipping. The table frame is pre-assembled at Q.V.P., with all junctions clearly marked for simple reassembly.

The model shown here is a 4 x 8 frame press, with outside dimensions of 56.5” x 104.5”, designed to press a standard 4 x 8 sheet of plywood. We also offer a 4 x 10 version and can custom-build a press to your exact specifications.

One customer used a truck winch to raise and lower the frame press table easily, showing how versatile the setup can be. He built a wall mount to attach the table

stand, with the distance from the wall determining how tall the pieces you can press are. A minimum distance of about six inches from the wall allows the press to

lean past ninety degrees without falling. Safety chains are included to ensure it stays securely in place.

Here is a short video of the press being raised and lowered