User-Friendly Guide to Vacuum Clamping for Woodworkers

Vacuum clamping is a game-changer in the woodworking shop. Many users say things like, "It's like having a third hand!" or "I don't know how I’d manage without it." If you have a vacuum pump, chances are you can start using vacuum clamping right away to make your work easier, safer, and more precise

Why Use Vacuum Clamping?

Vacuum clamping offers several advantages over traditional mechanical clamps:

No surface damage – Clamps won't leave marks on your materials.

Unobstructed tool access – No bulky clamps getting in the way of saws or routers, which improves safety.

Fast setup – Workpieces are secured quickly.

Even, uniform pressure – Unlike mechanical clamps that concentrate force in specific spots, vacuum applies pressure evenly across the entire surface (up to 1,800 lbs/sq. ft.).

For template routing, vacuum clamping makes templates lighter and helps you cut more accurate pieces.

Types of Vacuum Jigs and Their Uses

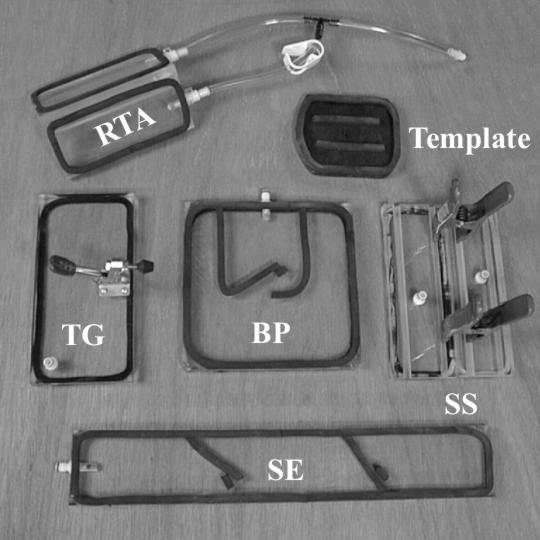

There are many vacuum jigs you can build or buy to improve productivity and safety. Below are a few examples (refer to the picture above for visuals):

Straight Edge (SE) – Can be placed anywhere on a workpiece, not just the edge.

Right Angle Clamp (RTA) – Ideal for securing two pieces at 90 degrees.

Baseplate (BP) – Holds stock 3/4" off the bench, floor, or wall, making routing or cutting easy

Toggle Clamp Jig (TG) Useful clamp for hard to place standard clamps

These are just the basics—your imagination is the limit! Some woodworkers build jigs for complex tasks, like assembling hexagons with 60 vacuum clamps.

Building a Vacuum Jig

When making a vacuum jig, follow these guidelines:

Materials: Use non-porous, flat materials. For long-lasting jigs, 3/4" plastic sheets work best (plastic is stable and doesn’t absorb moisture). Plywood, MDF, or

hardwood may work for quick jigs but can be porous or warp over time.

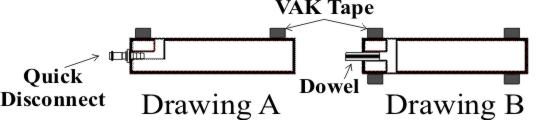

Design: Cut the jig to size and drill two intersecting holes for vacuum connections (see Drawing A).

Connections: Attach a quick disconnect fitting to the side hole. For quick jigs, a dowel inserted into the vacuum line can also work (see Drawing B).

Pro tip: If using air-line quick disconnects, ensure your jig is 1-1½" thick to avoid leaks and test fittings for vacuum-tight seals.

Using Gasket Tape for a Perfect Seal

The recomended vacuum hold down tape. Q.V.P. VAK-Tape

The right gasket tape is critical. It must be:

Closed-cell foam – Regular weather-seal tape won’t work.

Correct density – Too light, and it won’t spring back after repeated use. Too dense, and it won’t seal around slightly curved stock.

Appropriate thickness – If it’s too thick, it may cause the jig to rock during routing.

Testing for Leaks

To check your jig for leaks:

Connect it to your vacuum pump.

lock the vacuum hole(s) with your fingers and read the vacuum gauge.

If your pump normally pulls 27"Hg but reads only 20"Hg, there’s a leak somewhere. Check connections and fittings to make sure everything is tight.

Keep in mind that quick jigs made from wood may not achieve full vacuum levels, but they’ll still offer sufficient holding force for many tasks. Also elevation above

sea level will also effect your vacuum level.

Hands-Free Operation with a Foot Pedal

A foot pedal offers two key advantages:

Keeps your hands free – Ideal when lifting heavy pieces or using cutting tools.

Increases productivity Many users report up to 20% more efficiency, especially for tasks like template routing where multiple pieces are involved.

Conclusion

Vacuum clamping isn’t just a luxury—it can transform the way you work. From safer, faster setups to better precision, vacuum jigs make complex tasks easier and more efficient. Whether you build simple jigs or an advanced system, the possibilities are endless. Give it a try—you might wonder how you ever managed without it!