Softening Veneer for Successful Application

When working with raw wood veneers, it's essential to ensure the veneer is flat and flexible before use. If a veneer is too dry or wavy, it can crack during the pressing process, especially when applied to curved surfaces like raised panel doors. For a smooth application, the veneer must easily conform to the surface it’s being applied to.

Why use veneer softener?

If your veneer is brittle or curled, using a veneer softener helps make it pliable. Softened veneers are less likely to break when bent over curves (such as in Blog #1, used for curved panel doors) . This treatment ensures the veneer can conform smoothly without damaging the wood fibers.

Step-by-Step Veneer Softening Process

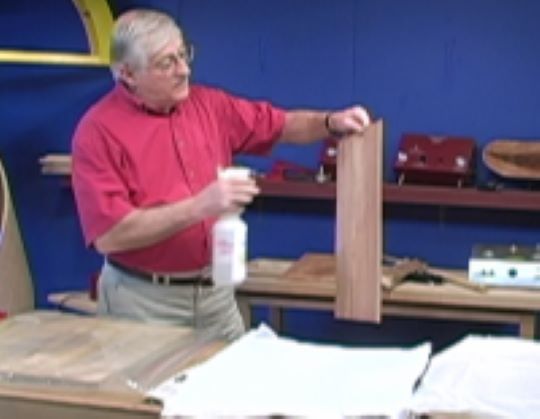

For best results, V-Flex veneer softener is diluted 1:1 with water and applied by spraying both sides of the veneer (P1). Once sprayed, the veneer is placed in a vacuum bag with a layer of plain paper on either side, along with a caul (a rigid flat board) on top to ensure even pressing.

Important Tips for Preparing Veneer in a Vacuum Press

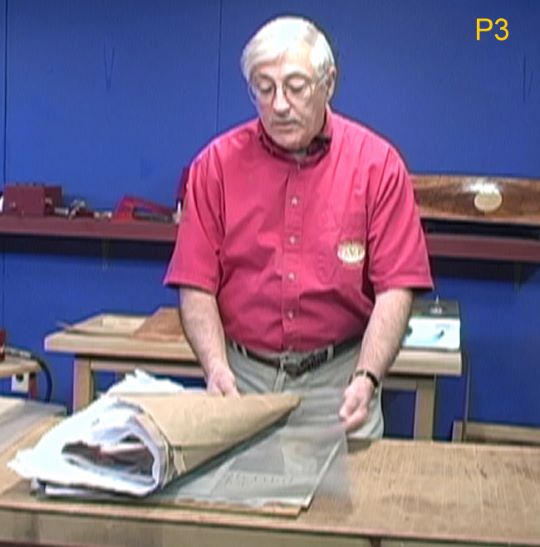

Paper Choice:

Avoid using newspaper directly on the veneer, as the ink can stain it. Instead, use plain brown paper bags or tissue wrapping paper (P2). If necessary, newspaper can be used on top of the brown paper, but it should never touch the veneer directly.

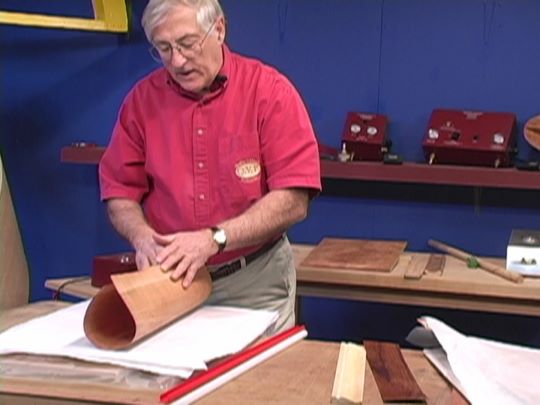

Moisture Wicking:

To speed up moisture removal, include a plastic mesh (like a window screen) (P3) between the paper layers. This mesh helps wick moisture away faster by allowing air to circulate.

Paper Changes:

As the vacuum press draws moisture from the veneer, replace the paper several times during the process to absorb excess water more effectively.

Applying Vacuum Pressure:

Place the prepared veneer stack in the vacuum press (P4) and activate the vacuum. This process removes moisture while flattening the veneer.

Monitoring Moisture Content (MC)

After removing the veneer from the press, it's critical to check its moisture content (MC) (P5) using a moisture meter. Veneer that’s too wet during pressing will expand, and

once it dries, it can shrink, causing crazing or cracking on the surface. This shrinkage risk is influenced by the type of wood and the moisture differential.

Pro Tip: Measure the MC at both the center and the edges of the veneer. The edges often dry faster, so uneven moisture levels can lead to warping or cracks once the veneer fully cures.

Proper Storage and Use of Softened Veneer

Once the veneer has been softened and its moisture content adjusted, it will remain flexible for several days. However, storage conditions can affect this timeframe, so it’s best

to use the veneer within a few days of softening.

This process ensures your veneer remains flexible and ready for seamless application, reducing the risk of cracking or damage during use.